Welcome to Yuncheng plate making group east China head office!

In the new fiscal year, new growth - the practice activity of improving equipment capacity and personnel efficiency of East China head office was successfully held

Release time:2022-03-11

Source: this website

In the new fiscal year, new growth - the practice activity of improving equipment capacity and personnel efficiency of East China head office was successfully held

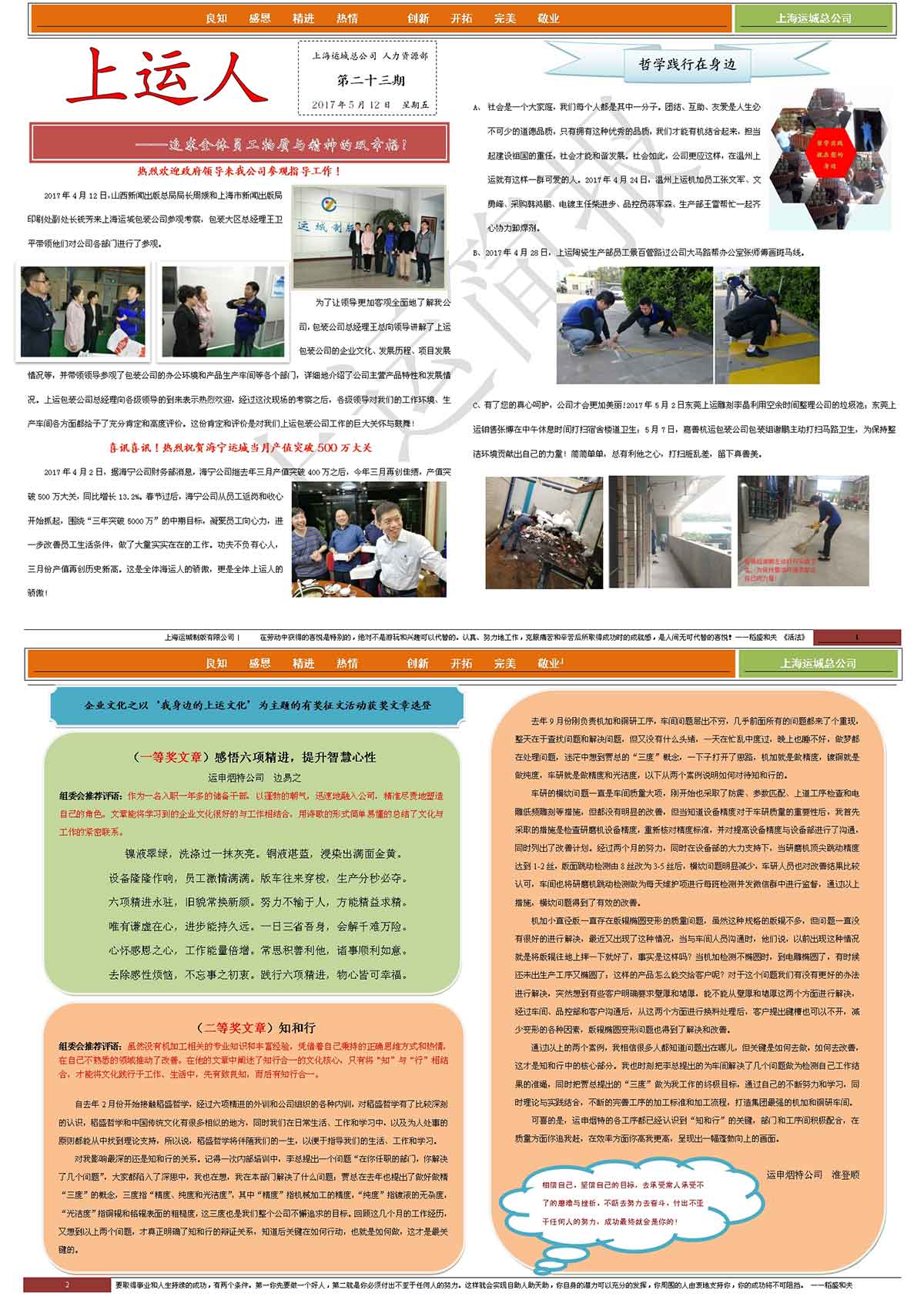

Equipment capacity and personnel efficiency are important leading indicators of internal production management of enterprises. Through the observation of standard working hours, the reference table of production capacity and efficiency can be calculated, which provides a basis for enterprises to arrange production and formulate investment plans. In order to ensure that all companies can give full play to the maximum capacity of equipment in the new fiscal year, the lean production department of East China head office organized senior executives of domestic plate making companies, heads of head offices and regional human resources departments to carry out practical activities to improve equipment capacity and personnel efficiency in Haining Yuncheng from November 22 to 26, 2021, led managers to study man hour observation and capacity accounting, and prepared SOP documents for the whole process, Jointly discuss the contents of Lean quality dual system to promote the sustainable and healthy development of enterprises.

On the morning of November 22, offline practice activities kicked off. Wang Weiping, deputy general manager of East China head office, mobilized and trained the Lean quality management dual system. The sustainable development of the enterprise needs the support of the whole process management system, the normal distribution of personnel assessment and incentive methods, and preventive management measures. Lean management is inseparable from the support of senior management and should play the role of leader. Gao Pan, the lean production department of the head office, and Li Binghong, the deputy general manager of yun'an packaging production, respectively trained man hour observation and capacity accounting methods, improved breakthrough methods, and shared lean production management knowledge.

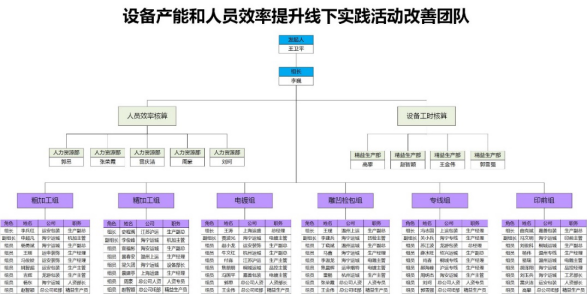

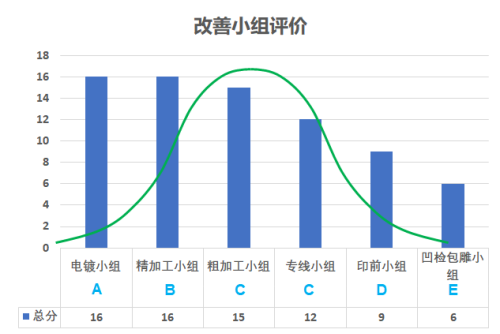

The lean production department of the head office carried out the preliminary planning, process management and summary output of the activities. The activities were carried out in accordance with the process of improvement and breakthrough method. Firstly, an offline practical activity improvement team for improving equipment capacity and personnel efficiency was established. Managers from 20 companies were divided into six improvement teams to conduct on-site observation, investigation and improvement of different processes. The whole process uses the improvement information form to realize the management of activity content, and adjusts the work content through daily summary and feedback. The improvement team found and solved problems on site, and successfully carried out 19 improvement projects in process, equipment and tooling, workflow and management mode. By organizing the evaluation of participants and the assessment of theoretical knowledge, the activity process and effect are effectively controlled.

During the five-day improvement practice activity, the management cadres of each company went deep into the scene to establish a "Moonlight factory", often worked late into the night, and worked hard to achieve full results for each participant. In this activity, the capacity reference table of key plate making equipment of East China head office was output, which provided data support for Haining Yuncheng to identify bottleneck processes, improve equipment capacity and personnel efficiency, provide scientific methods for East China companies to carry out capacity accounting and standardization improvement, and accumulate experience for East China head office to organize collective learning activities.

At the end of the event, an air bus event was held in Haining Yuncheng. Li Wei, general manager of Haining Yuncheng, first thanked everyone for their efforts and contributions in Haining Yuncheng, and was determined to lead the management team to establish the company as a lean management enterprise with high efficiency and high growth. Wang Weiping, deputy general manager of East China head office, encouraged all companies to actively carry out lean improvement, give full play to the efficiency of equipment and personnel through competition, constantly break through historical records and create new brilliance in the output value and benefit of East China head office!

"Thank you letter to dianai fund of East China head office"

Excerpt of excellent experience

In the new fiscal year, new growth - the practice activity of improving equipment capacity and personnel efficiency of East China head office was successfully held

New normal and new growth in the new fiscal year -- the speech contest and commendation meeting for outstanding employees of East China head office in fiscal year 2021 was successfully held

Commendation meeting for outstanding employees of East China head office in fiscal year 2021

Issue 25

Issue 24

Issue 23

Issue 22

To build a learning team, the special training of "increasing revenue and reducing expenditure in fiscal year 2020" of East China head office was kicked off